INTRODUCTION

STAR TRACE Magnetic Roller Separators are roll type dry magnetic separators with fixed magnet having high field intensity and gradient. The magnets used in the Roller Magnetic Separators and made of alloys of rare earth elements are more powerful as compared to other magnets. They generate high attraction forces on the magnetic roller due to their properties and special magnetic series. The obtained high magnetic attraction forces have low magnetic sensitivity and therefore they make it possible to separate very fine low magnetic minerals with a high recovery.

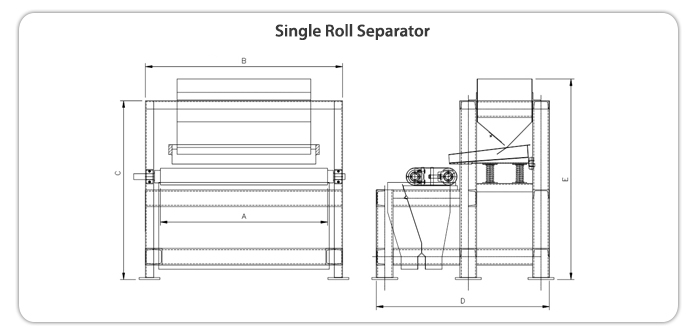

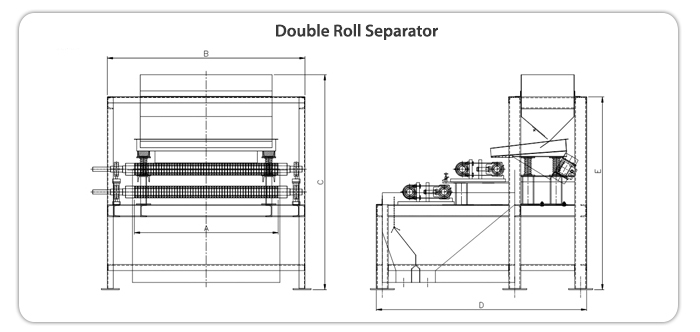

The most distinguishing property of Magnetic Roll Separators is the used magnets that are an alloy of rare earth elements produced domestically and more powerful. Magnetic Systems has a number of standard sizes in which the high gradient separator is produced, and all of these sizes only require a low installation height. It is also possible to make a system in accordance with customer specifications. Depending on the requirements made and the application, a choice can be made for a single stage system or for multiple magnet rollers under one another. This results in an even higher degree of iron separation.

Our latest developments in higher gauss value with star ultra super rare earth magnets with highest intensity,high gradient magnet arrangement in special proprietary configurations are now available after extensive research and development.

STAR TRACE is one of the Asia's leading manufacturing Company in Permanent Magnetic Equipments and Vibrating Equipments in Dry/Wet Separation of minerals and metals. The Dry Permanent Magnetic Roll Separator systems are unique in nature and we are supplying similar equipment throughout the world and more than 1000 Industries are having our Equipments. In our past 25 years of experience, we can separate from Coal to Gold in all minerals and metals from anywhere in the world, depending upon on their mining location, we are able to provide you complete solutions to upgrade your metals, minerals and your processes.

These Magnetic Roller Separators are highly effective of separating para magnetic particles and weakly para magnetic particles separately. These Rare Earth Magnetic Separators are made up of very high power specially developed Nickel, Iron Boron (Nd-Fe-B) with highest magnetic power available in the series to enable us to achieve very high gauss value compared to other similar products.

Right now, we have developed latest Magnetic Roll Separator with a diameter of 150mm which gives higher magnetic force and more contact area than the normal 100mm diameter magnetic rollers. These Magnetic Rollers are specially configured with configurations of suitable material sizes and its magnetic properties. The Magnetic Roll Separators have been passing through the belt which the material is running, is made of different materials with different thickness to suit effective beneficiation of separating minerals and metals.

These effective separators can be achieved with different thickness of belt ranging from 0.25mm to 2mm and some of the belt material which we have been using are having a non stick property and they are highly resistant to abrasiveness. Some of the belt material are coated with Nylon for its non stick property. These belts are basically made up of Kevlar, which is a Bullet Proof material and highest strength of its kind. These STAR TRACE Magnetic Roll Separators are having several passes to make sure of highest purity can be obtained by which several process repeatedly without much material handling. These Magnetic Roller Separators are primarily used in replacement of old technology of induced magnetic roller separators.

Magnetic Roller Separators Working Principle:

Magnetic Roller Separators consist of two rolls, one of which is magnetics. There is a belt between them to carry the ore into the magnetic field. The movement of the belt is controlled by a motor fixed to one of the rollers. The rotational speed of rollers can be adjusted according to the material properties

The material to be processed is conveyed to the belt by vibrating feeder at a required rate. Feeding rate can be controlled by adjusting the vibration on feeder. A Roller separator blade has been set in order to be able to collect separated products in different places and to adjust the product properties in a desired manner.

Magnetic Roller Separators Technical Features

- Field strength (measured indirectly and controlled by amp adjustment of the electromagnet) typically up to 15,000 gauss.

- Pole gap (closer the gap higher the field strength), typically 2mm.

- Roller speed ( normally fixed and only adjusted by pulley and belt changes).

- Splitter position (determined by visual observation of the fan).

- Feed temperature will affect magnetic susceptibility.

- Feed rate typically 2.5tph.